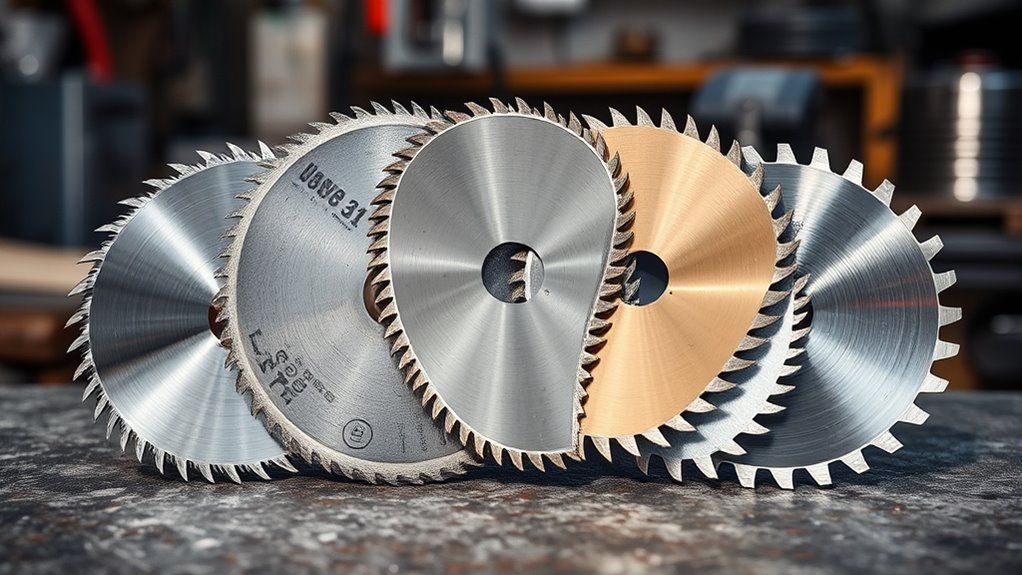

Finding angle grinder blades that cut metal precisely and last long can be a real challenge. If you’ve ever struggled with blades that wear out too quickly or don’t deliver clean cuts, you’re not alone. Many people face this frustration when working on metal projects and want reliable tools that make the job easier.

You want angle grinder blades that cut metal precisely and last long in 2026. Look for 4.5-inch wheels with reinforced fiberglass for safety, like DEWALT’s DW8062B5 or FOXBC’s diamond wheels, which offer over 5,000 clean cuts.

Ultra-thin thickness saves material and reduces dust, while diamond blades boost durability up to 100 times. Make sure the blade matches your grinder’s RPM to avoid breakage.

Keep exploring to uncover which blades fit your specific metalworking needs best.

| Image | Name | Editor's Rating | Price |

|---|---|---|---|

|

DEWALT 4-1/2 Inch Cut-Off Wheel, Angle G…

|

|

|

|

DeWalt DW8062 4-1/2"x.045"x7/8" Metal An…

|

|

|

|

FOXBC 4-1/2 Inch Diamond Cutting Wheel M…

|

|

DEWALT 4.5″ Cut-Off Wheel 5-Pack (DW8062B5)

- More Cuts. Fewer Wheels.TM

- 50% Longer Life* Replace wheels less often with Temper Point…

- Extremely Versatile: Efficiently cut a wide range of metals…

The DEWALT 4.5″ Cut-Off Wheel 5-Pack (DW8062B5) offers a reliable solution for cutting through various metals with precision and durability. Its thin .045-inch design ensures aggressive, clean cuts without leaving burrs, making metalwork smoother and faster. This wheel is engineered to last 50% longer than typical wheels, thanks to its Temper Point grain technology that maintains sharp edges during use.

Designed for use with angle grinders, it spins up to 13,300 RPM, delivering efficient cutting power for carbon steel, stainless steel, and nickel alloys. The wheel’s strength is enhanced by two fiberglass reinforcement sheets, which provide resistance to breakage and improve safety during operation. This design helps reduce downtime and tool changes, increasing work efficiency.

Maintenance is straightforward—regular inspection for wear and proper storage prolong its lifespan. The cut-off wheel is best suited for metalworkers who require consistent performance and durability in demanding jobs. While it excels in aggressive cutting, its medium grit (60) may not be ideal for ultra-fine finishing tasks.

Best for: Professionals and DIY enthusiasts seeking a durable cut-off wheel for fast, clean metal cutting with angle grinders.

What We Like:

- 50% longer life with Temper Point grains for lasting sharpness

- Thin design cuts aggressively without burrs

- Reinforced with two fiberglass sheets for added strength and safety

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4.5 inches |

| Thickness | 0.045 inches |

| Grit | Medium (60) |

| Maximum RPM | 13,300 |

| Material Compatibility | Carbon steel, stainless steel, nickel alloys |

| Reinforcement | Two fiberglass sheets |

| Compatible Tools | Angle grinders, bench die grinders |

| Pack Quantity | 5 wheels |

DeWalt DW8062 Metal Angle Grinder Cutoff Wheels (10)

- Thin . 045-Inch wheel design for fast burr free cutting this…

- This are highly durable this is manufactured in China

- Proprietary aluminum oxide grain combination for aggressive…

Experience precise and efficient metal cutting with the DeWalt DW8062 Metal Angle Grinder Cutoff Wheels. Designed to deliver fast, burr-free cuts, these 4-1/2″ wheels make metalworking smoother and more accurate. Their thin 0.045-inch thickness allows for aggressive cutting without sacrificing control.

The wheels feature a proprietary aluminum oxide grain that enhances cutting performance and longevity. Reinforced with two full fiberglass sheets, they maintain durability and safety during demanding tasks. This design helps reduce risks of breakage and ensures consistent operation.

Maintenance is straightforward—simply inspect the wheel for wear and replace when necessary to maintain optimal cutting quality. These cutoff wheels are compatible with select angle grinders such as the DEWALT DCG416B, making them suitable for a range of metal fabrication projects.

By focusing on precision and safety, these wheels reduce the need for additional finishing work, saving time and effort. However, their thin profile may not be the best fit for very heavy-duty cutting needs where thicker wheels are preferable.

Best for: Professionals and DIY enthusiasts seeking fast, precise, and burr-free metal cutting with compatible angle grinders.

What We Like:

- Thin design enables aggressive and precise cuts.

- Fiberglass reinforcement enhances durability and safety.

- Proprietary aluminum oxide grain improves cutting efficiency.

- Compatible with DEWALT angle grinders for versatile use.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4-1/2 inches |

| Thickness | 0.045 inches |

| Abrasive Material | Proprietary aluminum oxide grain |

| Reinforcement | Two full fiberglass sheets |

| Compatibility | DEWALT DCG416B and similar grinders |

| Quantity per Pack | 10 wheels |

| Intended Use | Metal cutting with angle grinders |

| Origin | Manufactured in China |

FOXBC 4.5″ Diamond Cutting Wheel 3-Pack

- Diamond rimmed wheels deliver up to 100X longer cutting life…

- Ideal for dry cutting of metal, rebar, angle iron, cast…

- Advanced Electro-Plating Process for even distribution of…

The FOXBC 4.5″ Diamond Cutting Wheel 3-Pack offers a reliable solution for cutting a variety of metals with precision and longevity. These wheels are specifically engineered to handle tough materials like rebar, stainless steel, and aluminum, helping you complete your tasks efficiently without frequent replacements.

Each wheel features a diamond rim that not only extends cutting life up to 100 times longer than standard discs but also enhances safety by reducing sparks and dust. This design minimizes the risk of breakage, providing confidence during heavy-duty cutting projects.

Advanced electro-plating technology ensures an even distribution of diamond abrasive. This results in superior control and accuracy, allowing you to make clean, precise cuts every time. Maintenance is simple since the wheels maintain their performance over thousands of cuts, reducing downtime and improving productivity.

These cutting wheels require a compatible 4.5-inch angle grinder, making them ideal for users with the proper tools. While they excel on hard metals, they may be less effective on very soft or specialized materials not listed.

Best for: Professionals and DIY enthusiasts looking for durable, precise diamond cutting wheels designed for multiple metal types.

What We Like:

- Up to 100 times longer cutting life than standard discs

- Diamond rim reduces sparks, dust, and breakage risk

- Even diamond abrasive distribution for precise cuts

- Over 5,000 cuts per wheel for enhanced productivity

Specification:

| Specification Title | Detailed Description |

|---|---|

| Diameter | 4.5 inches |

| Pack Quantity | 3 wheels |

| Compatible Grinder Size | 4.5-inch angle grinders |

| Materials Suitable For | Rebar, stainless steel, aluminum, and various metals |

| Cutting Life | Up to 100 times longer than standard discs |

| Number of Cuts per Wheel | Over 5,000 cuts |

| Safety Features | Diamond rim reduces sparks, dust, and breakage risk |

| Abrasive Technology | Advanced electro-plating for even diamond spread |

FIXLTFAST Diamond Metal Cutting Wheel 4.5″ 3-Pack

- 【Accurate Cutting】FIXLTFAST metal cutting wheel 4 1 2 in…

- 【Avoid Injury】FIXLTFAST 4 1 2 diamond cutting wheel…

- 【Compatibility】1 equals 100, the diamond cutting wheel…

The FIXLTFAST Diamond Metal Cutting Wheel 4.5″ 3-Pack offers a practical solution for those who need efficient and precise metal cutting. Designed with a high-manganese steel body and serrated edges, these wheels enhance cutting speed and durability. The advanced electroplating technology boosts cutting efficiency by 50%, helping you finish jobs faster and with less effort.

These wheels are engineered for dry cutting applications and handle materials like iron, alloy steel, aluminum, and pipes with ease. The 24-hole design not only reduces sparks but also improves control, making it safer to operate at speeds up to 13,200 RPM. This design minimizes heat buildup, which helps extend the wheel’s lifespan.

Maintenance is straightforward since the wheels are built to resist damage during use and come individually packaged to prevent chipping or wear before first use. The included arbor assemblies accommodate both 4/5 inch and 5/8 inch shafts, making these wheels compatible with most angle and bench grinders.

While these wheels are robust, users should note they require full safety gear during operation, and their thickness of 0.047 inches is best for general metal cutting rather than ultra-fine tasks.

Best for: Professionals and hobbyists who require durable, efficient cutting wheels for various metalworking projects with angle or bench grinders.

What We Like:

- High-manganese steel with advanced electroplating increases cutting efficiency.

- 24-hole design reduces sparks and enhances user control.

- Compatible with multiple arbor sizes for versatile grinder use.

- Individually packaged wheels prevent damage during storage and transport.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4.5 inches |

| Pack Quantity | 3 wheels per pack |

| Material Composition | High-manganese steel with diamond electroplating |

| Cutting Thickness | 0.047 inches |

| Maximum Speed | 13,200 RPM |

| Arbor Compatibility | 4/5 inch and 5/8 inch shafts |

| Application Type | Dry cutting of iron, alloy steel, aluminum, pipes |

| Design Features | Serrated edges, 24-hole design for spark reduction |

| Packaging | Individually packaged wheels |

EZARC 4.5″ Diamond Cutting Wheel for Metal

- [Diamond Technology] 1 equals 100, EZARC diamond cut off…

- [All in 1 Metal Solution] Ideal for dry cutting of metal,…

- [Avoid Injury] Solid steel wheel body greatly reduces risk…

The EZARC 4.5″ Diamond Cutting Wheel for Metal is designed to deliver precision and durability for tough metal cutting tasks. It effortlessly slices through metal, rebar, steel, and aluminum, providing over 5,000 clean cuts. This longevity means you spend less time changing wheels and more time working.

Its solid steel body enhances safety by reducing the risk of shattering during use. This feature also helps minimize dust, keeping your workspace cleaner and healthier. The cutting wheel maintains its original diameter throughout its life, ensuring consistent control and smooth operation.

Maintenance is simple since the wheel’s durable design requires less frequent replacement. It fits tools that accommodate a 4.5″ diameter and 7/8″ arbor size, making it compatible with many standard angle grinders. This wheel is specialized for metalwork and not intended for cutting non-metal materials.

By combining industrial-grade quality with extended lifespan, this cutting wheel supports efficient and safe metalworking projects without frequent interruptions.

Best for: Professionals and DIY enthusiasts needing a durable and precise cutting wheel for metal fabrication and repair.

What We Like:

- Lasts for over 5,000 cuts, greatly extending tool uptime.

- Solid steel construction reduces shatter risk and enhances safety.

- Maintains diameter for consistent cutting performance.

- Produces less dust, improving worksite cleanliness.

- Fits standard 4.5″ x 7/8″ angle grinders for versatile use.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Diameter | 4.5 inches (115 mm) |

| Arbor Size | 7/8 inch (22.23 mm) |

| Material Compatibility | Metal, rebar, steel, aluminum |

| Maximum Cuts | Over 5,000 clean cuts |

| Body Material | Solid Steel |

| Intended Use | Metal cutting |

| Safety Features | Reduced shatter risk, dust minimization |

50 Pack 4.5″ Metal Cutting Wheels for Grinder

- 【50 PACK】This is for a pack of 50 pieces of our cutting…

- 【MATERIAL】Proprietary aluminum oxide grain for long life…

- 【PERFORMANCE】Skinny 0.045″ cutting wheel design for fast…

Cutting through metals can be challenging without the right tools. The 50 Pack 4.5″ Metal Cutting Wheels for Grinder offers a solution that makes metal cutting fast and precise. These wheels are designed with a thin 0.045-inch profile, which enables quick, burr-free cuts on various metal types.

Each wheel incorporates proprietary aluminum oxide grain, enhancing durability and ensuring the cutter stays sharp longer. The double fiberglass mesh reinforcement adds a layer of strength and safety, allowing operation at speeds up to 13,300 RPM without compromising performance or user security.

Maintenance is straightforward: keep the wheels clean and dry, and inspect regularly for any damage before use. These cutting wheels are intended for use with any 4.5-inch angle grinder featuring a 7/8-inch arbor. They excel at cutting carbon steel, stainless steel, cast iron, and similar metals, making them ideal for projects involving pipe, rebar, or metal sheets.

While these wheels offer excellent cutting performance, they are not designed for non-ferrous metals like aluminum or plastic. Users should always wear appropriate protective equipment due to the high-speed operation involved.

Best for: Professionals and DIY enthusiasts seeking efficient, fast, and clean metal cutting solutions compatible with standard 4.5-inch angle grinders.

What We Like:

- Durable aluminum oxide grain ensures long-lasting sharpness.

- Double fiberglass mesh reinforcement enhances safety and strength.

- Thin 0.045-inch design delivers fast, clean cuts with minimal burrs.

- Compatible with all 4.5-inch angle grinders with a 7/8-inch arbor.

- Suitable for cutting a variety of ferrous metals including steel and cast iron.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4.5 inches (115 mm) |

| Thickness | 0.045 inches (1.2 mm) |

| Material Grain | Proprietary aluminum oxide |

| Reinforcement | Double fiberglass mesh |

| Maximum Operating Speed | 13,300 RPM |

| Arbor Size | 7/8 inch (22.23 mm) |

| Compatible Grinder Size | 4.5-inch angle grinders |

| Suitable Materials | Carbon steel, stainless steel, cast iron |

| Unsuitable Materials | Non-ferrous metals like aluminum or plastics |

10 Pack 4.5″ Ultra Thin Cut Off Wheels

- Structural Components: A Cut off wheel typically comprises…

- Working principle: As the grinding wheel rotates at high…

- Cutting performance: It adopts a 1/64-inch thin cutting…

Experience precision cutting like never before with the 10 Pack of 4.5″ Ultra Thin Cut Off Wheels. Designed for efficient slicing through various metals, these wheels deliver clean cuts with minimal effort. Their ultra-thin 1/64-inch profile reduces material waste and enhances control during use, making metalwork smoother and more accurate.

Each wheel incorporates strategically placed air holes that help dissipate heat, preventing overheating and prolonging wheel life. This feature ensures consistent performance even in demanding projects. The abrasive surface is tailored to handle carbon steel, stainless steel, iron, pipes, and copper, providing versatility across many applications.

Maintenance is simple—inspect wheels regularly for damage and replace them promptly to maintain safe operation. Proper installation is crucial; securely fastening the wheel on any 4-1/2 inch angle grinder minimizes breakage risks. Always adhere to safety guidelines, including wearing protective gear, to ensure safe and effective cutting.

These cut off wheels are ideal for automotive repairs, construction tasks, and general hardware work where precision and speed matter. Their compatibility with all standard 4-1/2-inch grinders adds convenience, making them a practical choice for both professionals and DIY enthusiasts.

Best for: Professionals and hobbyists seeking precise and efficient metal cutting with a 4-1/2-inch angle grinder.

What We Like:

- Ultra-thin 1/64-inch design enables fast, clean cuts

- Air hole design reduces heat buildup, extending wheel life

- Compatible with all 4-1/2-inch angle grinders

- Suitable for cutting various metals like steel, iron, and copper

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4.5 inches (115 mm) |

| Wheel Thickness | 1/64 inch (approximately 0.4 mm) |

| Pack Quantity | 10 wheels |

| Compatible Grinder Size | 4-1/2 inches (115 mm) |

| Material Compatibility | Carbon steel, stainless steel, iron, pipes, copper |

| Heat Dissipation Feature | Air holes integrated into wheel design |

| Maximum Operating Speed | 13,300 RPM |

| Safety Precautions | Use with proper protective gear and secure installation |

Diamond Cutting Wheel 4.5 Inch Metal Cut-Off Disc

- 【IDEAL SIZE】With a diameter of 4.5″ (115mm), segments…

- 【PRECISE METAL CUTTING】Achieve accurate, chip-free cuts…

- 【SHARP BLADE】WildBossy diamond cutting blade cuts fast…

The Diamond Cutting Wheel 4.5 Inch Metal Cut-Off Disc offers a powerful solution for cutting tough metals with ease and precision. Designed to handle materials like rebar, steel, and INOX, it ensures smooth, chip-free results that save time and effort on every project.

Crafted from high manganese steel with a diamond substrate, this disc is engineered for exceptional durability, capable of delivering over 5000 clean cuts. Its upgraded blade design and brazing process enhance cutting accuracy, making it a dependable tool for both professionals and DIY users.

The disc’s 4.5-inch diameter and 7/8-inch arbor size fit most standard angle grinders, while included reducer washers allow for compatibility with different arbor sizes. This versatility means it can easily be installed and swapped out when needed, streamlining your workflow.

Lightweight and designed to resist high temperatures, the disc also reduces noise during operation, improving comfort and safety. Regular inspection and proper storage will help maintain its cutting performance over time.

Best for: Professionals and DIY enthusiasts needing a durable, precise cutting disc for tough metals like rebar, steel, and INOX.

What We Like:

- Long-lasting blade capable of over 5000 cuts on hard metals

- Smooth, chip-free cutting due to advanced blade design

- Fits most angle grinders with included reducer washers for arbor adaptability

- Lightweight and heat-resistant for improved handling and durability

- Noise reduction features enhance user comfort during use

Specification:

| Specification Title | Detailed Description |

|---|---|

| Blade Diameter | 4.5 inches (115 mm) |

| Arbor Size | 7/8 inch (22.23 mm) |

| Material | High manganese steel with diamond substrate |

| Cutting Capacity | Suitable for rebar, steel, and INOX |

| Blade Thickness | 1.73 mm |

| Maximum RPM | Compatible with standard angle grinder speeds |

| Included Accessories | Reducer washers for different arbor sizes |

| Weight | Lightweight design for easy handling |

| Heat Resistance | High tolerance to heat during cutting |

| Noise Level | Reduced noise operation for enhanced comfort |

SALI 50 Pack 4.5″ Metal Cutting Wheels

- Size :4-1/2-inch x .047-inch x 7/8-inch

- Performance: this is for a pack of 50 pieces of our cutting…

- Advantage: thin .045-inch wheel design for fast burr free…

The SALI 50 Pack 4.5″ Metal Cutting Wheels is designed to meet the demands of heavy metal cutting with efficiency and precision. These cutting wheels provide fast, clean cuts on various metals, including stainless steel, helping you complete your projects with less effort and better results.

Each wheel features a thin .045-inch design that minimizes material waste and reduces burr formation. This ensures smoother edges and less finishing work after cutting. The wheels are reinforced with double fiberglass mesh for added durability and enhanced safety during use.

Maintenance is straightforward; simply inspect wheels regularly for wear and replace as needed to maintain cutting performance. These wheels are compatible with all 4-1/2 inch angle grinders sporting a 7/8-inch arbor and can safely operate at speeds up to 13,300 RPM, making them versatile for most metal cutting tools.

With a bulk pack of 50 wheels, you have a consistent supply ready for frequent use, ideal for busy workshops. However, occasional users should consider storage needs due to the quantity. Always prioritize safety by wearing proper protective gear when cutting.

Best for: Professionals and DIY enthusiasts who require a reliable, high-quality supply of cutting wheels for frequent metal and stainless steel cutting tasks.

What We Like:

- Thin .045-inch wheels enable fast, burr-free cuts.

- Double fiberglass mesh reinforcement enhances safety and durability.

- Compatible with all 4-1/2 inch angle grinders with 7/8-inch arbor.

- Handles speeds up to 13,300 RPM for versatile use.

- Bulk pack ensures a steady supply for frequent projects.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Wheel Diameter | 4.5 inches |

| Wheel Thickness | 0.045 inches |

| Material Composition | Proprietary aluminum oxide grain |

| Reinforcement | Double fiberglass mesh |

| Arbor Size | 7/8 inch |

| Maximum Operating Speed | 13,300 RPM |

| Quantity | 50 wheels per pack |

| Compatible Tools | All 4-1/2 inch angle grinders with 7/8-inch arbor |

4.5″ Cut Off Wheel Grinder Discs, 10 Pack

- [High-Performance Cutting] Designed for cutting metal &…

- [Dual Alumina Composition] These grinding wheels 4 1/2 inch…

- [Ultra-Thin & Efficient] At just 0.045″ thick, these cutting…

Experience precise and efficient metal cutting with the 4.5″ Cut Off Wheel Grinder Discs, 10 Pack. These discs are designed to deliver smooth, accurate cuts, reducing material waste thanks to their ultra-thin 0.045-inch thickness. They allow you to work cleanly and effectively on a variety of metal projects without compromising quality.

Crafted with a dual alumina composition, these grinder discs handle both stainless and carbon steel with ease. This composition not only improves durability but also enhances cutting speed, making your tasks faster and more efficient. The discs maintain performance even under demanding conditions.

Operating at a maximum speed of 13,300 RPM, these discs are compatible with most angle grinders. The fine grit (60) ensures a clean finish on steel pipes, rebar, and similar materials. Reinforced for wear resistance, they offer long-lasting reliability for heavy use.

Maintenance is straightforward—store the discs in a dry place to preserve their cutting edge and ensure consistent performance every time. Their design balances precision and durability to meet the needs of professionals and hobbyists alike.

Best for: Professionals and DIY enthusiasts requiring precise, efficient metal and stainless steel cutting with an angle grinder.

What We Like:

- Ultra-thin 0.045-inch thickness for precise, clean cuts with minimal waste.

- Dual alumina composition boosts durability and cutting speed on various metals.

- Reinforced build provides excellent wear resistance during heavy-duty use.

- Suitable for cutting steel pipes, rebar, and similar materials with a fine grit finish.

Specification:

| Specification Title | Detailed Description |

|---|---|

| Disc Diameter | 4.5 inches |

| Thickness | 0.045 inches |

| Grit | 60 (fine grit) |

| Material Composition | Dual alumina |

| Maximum Speed | 13,300 RPM |

| Quantity | 10 discs per pack |

| Compatible Materials | Stainless steel, carbon steel, steel pipes, rebar |

| Reinforcement | Wear-resistant construction |

Factors to Consider When Choosing an Angle Grinder Blade for Cutting Metal

When you’re picking an angle grinder blade for cutting metal, there are a few things you really want to keep in mind. First off, consider the blade material, thickness, and grit size carefully. These factors make a big difference in how well the blade will perform.

Also, it’s important to make sure the blade matches your grinder’s speed. Using the right blade for your tool not only improves efficiency but also helps the blade last longer. And of course, don’t forget about durability—it’s key to getting the job done without having to swap blades constantly.

Last but definitely not least, safety should always be your top priority. Choosing the right blade and using it properly means you’ll get the best performance without putting yourself at risk. So, take your time picking out the blade that fits your needs and your grinder perfectly.

Blade Material Types

Choosing the right blade material is essential for efficient and safe metal cutting with an angle grinder. You’ll mainly encounter aluminum oxide and diamond blades. Aluminum oxide suits general-purpose cutting and handles most metals well.

Diamond blades excel in durability and precision, lasting up to 100 times longer than standard discs. They’re ideal if you’re tackling tougher materials or high-volume jobs.

Furthermore, look for blades reinforced with fiberglass. It boosts safety by reducing breakage risks. The grit type matters too: medium grit (around 60) works well for everyday metal cutting, while finer grits give smoother finishes on softer metals.

Cutting Wheel Thickness

After deciding on the right blade material, you’ll want to think about the thickness of the cutting wheel. Thickness usually ranges from 0.040 to 0.068 inches. Thinner wheels, around 0.045 inches, are great for fast, burr-free cuts and help reduce material waste.

This makes them perfect for precision metalwork. On the other hand, thicker wheels offer greater durability and resist breakage better. But they cut slower and generate more heat.

For general metal cutting, a medium thickness near 0.045 inches strikes a good balance between speed and strength. Also, keep in mind the type of metal you’re cutting. Tougher metals often need thicker wheels to handle the higher cutting stress.

Grit Size Importance

Since grit size directly affects how your angle grinder blade interacts with metal, understanding its importance can markedly improve your cutting results. Grit size, measured numerically, indicates the abrasive’s coarseness. Lower numbers mean coarser grits, higher numbers finer ones.

Medium grit wheels, like those around 60, strike a good balance between cutting speed and surface finish. This makes them ideal for general metal cutting. If you want smoother cuts with less finishing, choose finer grits. Just be aware they wear out faster under heavy use.

Coarser grits remove material quickly but may leave rough edges and risk overheating your workpiece. Picking the right grit size not only guarantees peak cutting performance but also extends your blade’s life. It does this by preventing unnecessary wear and damage.

Speed Compatibility

Understanding grit size helps you select the right blade, but you also need to take into account speed compatibility when cutting metal. The maximum rotational speed of your angle grinder blade is essential for both efficiency and safety. Most cutting wheels are rated up to 13,300 RPM; using a blade beyond its speed limit risks breakage and accidents.

Thin cutting wheels, about 0.045 inches thick, are built for high-speed use. They give you quick, precise cuts with minimal material waste. To guarantee peak performance, match the blade’s maximum speed with your grinder’s RPM capability.

Always check the manufacturer’s specifications for both tools. Mismatched speeds reduce cutting efficiency and increase hazards. Prioritizing speed compatibility keeps your work safe and effective.

Durability And Safety

When you choose an angle grinder blade, durability and safety should be top priorities to guarantee reliable performance and protect yourself during metal cutting tasks. Look for blades with double fiberglass mesh reinforcement to reduce the risk of wheel breakage. Thin cutting wheels around 0.045 inches thick offer fast, burr-free cuts while improving safety by minimizing material waste.

High-quality blades often use proprietary aluminum oxide grain compositions that extend cutting life and maintain performance. Safety features like solid steel wheel bodies and advanced electroplating help prevent shattering and injury. Always check the blade’s maximum rotational speed, up to 13,300 RPM, to verify it matches your grinder.

Application Suitability

Although many angle grinder blades look similar, choosing one that suits your specific metal cutting task can greatly affect your results. You’ll want to take into account the blade’s thickness. Around 0.045 inches is ideal for fast, burr-free cuts on various metals.

Medium grit blades, roughly grit 60, offer versatility, handling carbon steel and stainless steel efficiently. Don’t overlook the blade’s maximum speed rating. Make sure it matches your grinder’s RPM to maintain cutting quality and safety.

The blade design matters too. Ultra-thin or diamond-tipped blades excel on tougher materials like rebar or stainless steel. Finally, always confirm compatibility with your angle grinder model to guarantee proper fitting, performance, and safety.

Picking the right blade tailored to your application makes all the difference in quality and efficiency. It’s worth taking a moment to get it right!

Frequently Asked Questions

How Do I Safely Dispose of Used Angle Grinder Blades?

You might think tossing used angle grinder blades in regular trash is fine, but it’s unsafe and illegal in many areas. To safely dispose of them, first, carefully wrap the blades in heavy-duty tape or place them in a rigid container to prevent injuries.

Then, take them to a local recycling center or hazardous waste facility. This way, you protect yourself, others, and the environment from sharp, potentially dangerous metal waste.

Can Angle Grinder Blades Be Sharpened for Reuse?

Yes, you can sharpen angle grinder blades for reuse, but it depends on the blade type. For metal-cutting blades, especially diamond or carbide-tipped ones, sharpening is tricky and often not worth the effort.

If you have a simple abrasive disc, it’s usually better to replace it once worn out. If you decide to sharpen, use a specialized tool or take it to a professional to maintain safety and effectiveness.

What Maintenance Tips Extend Blade Lifespan?

Oh sure, just toss your blade around like it’s a frisbee and expect it to last forever! To actually extend its lifespan, you’ve got to clean the blade after every use, avoid overheating by not forcing the cut, and store it in a dry place to prevent rust.

Also, regularly inspect for damage and replace worn discs promptly. Treat your blade well, and it won’t quit on you mid-job.

Are There Specific Blades for Cutting Stainless Steel?

Yes, you’ll find specific angle grinder blades made for cutting stainless steel. These blades usually feature fine, dense teeth or are made from materials like carbide or diamond grit to handle stainless steel’s toughness without dulling quickly.

Using the right blade guarantees cleaner cuts and longer blade life. Always check the blade’s specifications to confirm it’s designed for stainless steel, so you get the best performance and safety during your projects.

How Do Temperature Changes Affect Blade Performance?

Think of temperature changes like a rollercoaster for your blade. When it heats up, the metal expands and softens. This makes the blade less sharp and more prone to wear.

If it cools too quickly, it can become brittle and crack. You’ll want to keep your blade cool and steady, avoiding extreme heat spikes. That way, it stays sharp and durable.

With the right care, your blade will cut through metal smoothly without losing its edge. So, managing temperature is key to good blade performance.

Conclusion

Choosing the right angle grinder blade is like picking the perfect key to access your metal-cutting potential. With the options we’ve covered, you can confidently slice through any project with precision and ease.

Remember to consider durability, compatibility, and cutting speed to get the best results. Equip yourself with the right blade, and you’ll turn tough metal into smooth, clean cuts every time.

By choosing the best angle grinder blades for cutting metal, you’ll make your work not just easier but truly sharp and efficient.